Magnetic drums and belt pulleys

Drum separators are used to remove impurities from ferromagnetic large amounts of raw materials and deploying mainly waste management in municipal waste, processing of plastic, wood, mining industry. Their advantage is direct contact with the separated material magnet separator and automatic separation.

There are three types of drum separation system:

- magnetic barrel - the magnetic system comprises a magnetic sector with an angle of 180 °, which rotate around the drum of stainless steel. They are used usually for conveyor belts.

- drum magnets with covers - are actually drum magnets placed in the enclosure, and drive outputs of raw material and ferromagnetic impurities separated out. Installing for conveyor belts, piping systems, slipways or the like.

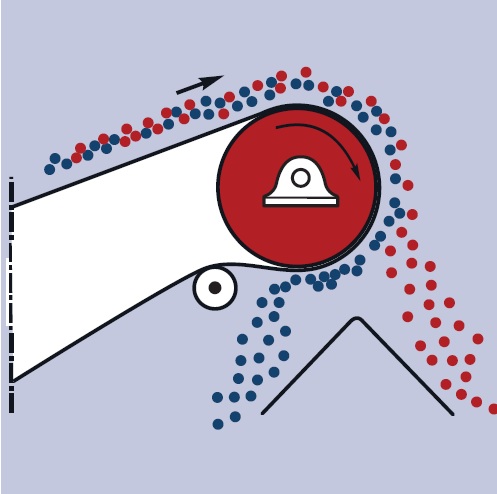

- Magnetic drive rolls - the magnetic system is made of solid magnetic sector with an angle of 360 °. They are used instead of reversing drum conveyor belt.

The operating principles of drum magnets:

.jpg) |

.jpg) |

|

| Magnetic drum | Magnetic drum with cover | Magnetic head pulley |

Magnetic drums and belt pulleys

Drum magnetic separator for conveyor belts.

Availability

Usually ships in: In stock

Drum magnetic separator

Ask for Pricing

from

The magnetic conveyor roller replaces the ordinary conveyor roller at the end of the conveyor belt.

Availability

Usually ships in: On demand

Magnetic conveyor roller

Ask for Pricing

from

A simple modular system that can be easily integrated to existing metal recycling systems.

Availability

Usually ships in: On demand

Drum magnetic separator with cover

Ask for Pricing

from

.svg)

.svg)