Plate and chute magnets

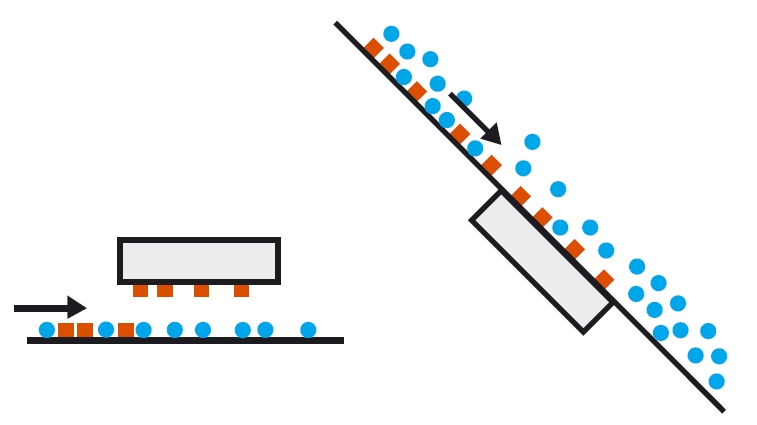

Plate magnets are used for removing ferromagnetic particles from the material flow on the conveyor belts, vibrating feeders, during free fall, in vertical or inclined pipeline systems, the slides and the like. These types of plate magnets are equipped with strong neodymium magnets that ensure strong and deep magnetic field, thus optimizing separation. The magnets are installed as close to the shipped material to achieve efficient separation of the different conditions depending on the product to be transported, the particle size and the speed of the transported material.

Power - Mag magnetic separator, EHEDG

Tube magnetic separator with automated cleaning POWER-MAG

Sanitary chute separators, automatic

Sanitary chute magnetic separators, pressurized

Chute magnetic separator, sanitary

Plate magnets, sanitary

Methods of installation of plate magnets:

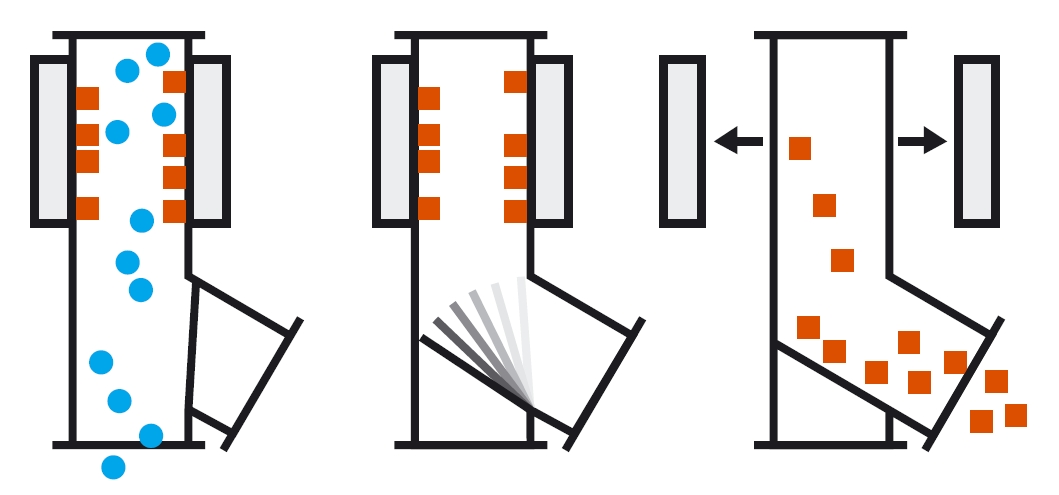

Slide-separators have been developed for the efficient separation of the iron particles from products that do not strike the pipeline, as a powder, wet and oily-like material and / or scrap. A separator is installed in the pipe in which the transported material, which may contain iron impurities. Slide-separators have a magnetic system arranged on the outside, so that the interior of the pipe is free, and nothing to prevent the flow of the raw material and the clogging of the pipe. Separators are equipped with thatched magnets Neodymium magnet system, embedded medziplatňami to simplify and accelerate the separator cleaning and after consultation with the technical department, it is possible to deploy them to the sloping pipes. Some types can also be used for systems with pressure Transport resources, systems with horizontal pneumatic transport can be supplied on demand.

The principle of operation of separators slip:

.svg)

.svg)